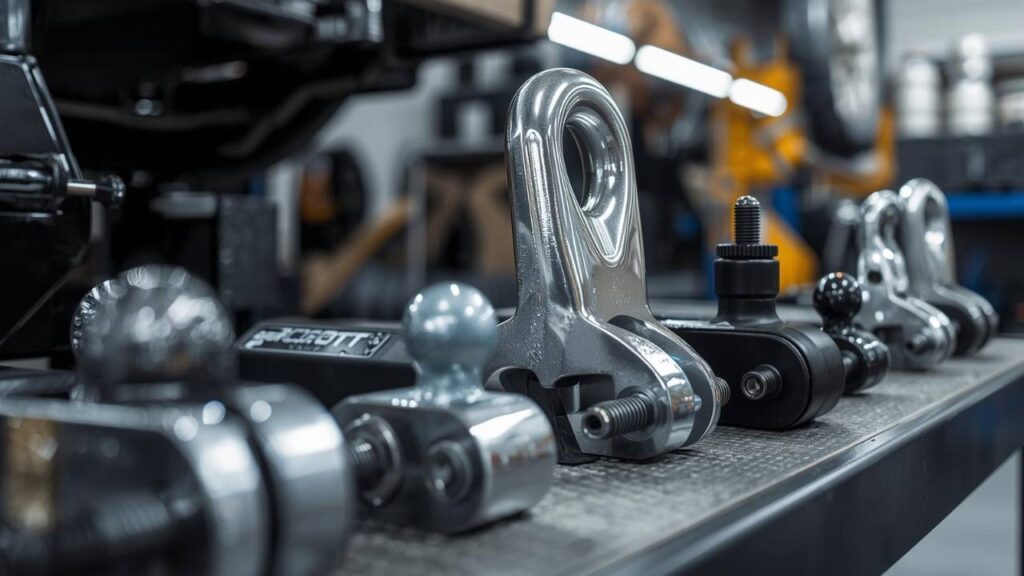

Trailer hitch balls are essentially basic elements of any towing system, which is the key to connecting your car to the Allinurl: Automotive towing equipment hitches balls. These small but critical devices serve as the tipping point to safe and regulated towing. To suit trailers and loads of different sizes and capacities, automotive towing equipment hitches balls are available in different sizes and capacities. Basically, the hitch ball attaches to your hitch receiver on your vehicle and the coupler on the trailer attaches to the ball and forms a secure fit. The first step to safe and efficient towing is to have an understanding of how hitch balls operate and how they fit into the towing system.

Even the strongest tow vehicle and the best-kept-trailer will be unsafe on the road without the right hitch ball. The following guide will take you through all the information you will need to know when choosing, installing, and maintaining the correct hitch ball 16.

📏 Hitch Ball Sizes Explained

With regards to the size of hitch balls, there are four standard diameters: 1-7/8 inches, 2 inches, 2-5/16 inches, and 3 inches. All sizes are intended to be used in particular towing and weight. Light-duty towing Typically the 1-7/8-inch ball is employed to pull a small utility trailer or a jet ski, and its capacity is often limited to 3,500 pounds. Most typical and used size is the 2-inch ball which fits most class III hitches and is appropriate with medium-duty trailers such as boats and campers with a 3,500-12,000 pounds capacity. On heavier loads, the 2-5/16-inch ball is applied, up to 30,000 pounds, and is common with large travel trailers or equipment. Gooseneck trailers and extreme heavy-duty applications are in the 3-inch ball. You want to ensure that you have an exact fit between the ball size and the coupler of your trailer 15.

Table: Standard Trailer Hitch Ball Sizes and Capacities

| Ball Diameter | Typical Use Case | Weight Capacity Range |

| 1-7/8 inches | Light-duty trailers | Up to 3,500 lbs |

| 2 inches | Medium-duty trailers | 3,500 – 12,000 lbs |

| 2-5/16 inches | Heavy-duty trailers | 6,000 – 30,000 lbs |

| 3 inches | Gooseneck trailers | Around 30,000 lbs |

🛠️ Choosing the Right Hitch Ball

When choosing the right hitch ball, it is not just a matter of matching sizes. There are three important factors that should be taken into consideration: the size of coupler, the size of shank and weight carrying capacity. First, the ball diameter should perfectly fit your coupler hole at the rear of your trailer–there is no bargaining on this, it is a point of safety. Second, the correct diameter and length of the shank (the part that inserts into the ball mount) should be able to safely pass through the hole in your hitch platform. It can move dangerously with a shank that is too small, and it will not fit a shank that is too big. Finally, the weight of the hitch ball should be bigger than your gross trailer weight (GTW).

The stamped values on the ball and coupler must always be checked by the manufacturer. Also, keep in mind the increase or decrease required to maintain your trailer level as this influences towing stability 15.

⚙️ 2-Inch Trailer Hitch Ball

The 2-inch trailer hitch ball can be considered the most flexible and widely used. The reason behind its popularity is that it fits class III hitches which are the most popular hitch type installed. This is a size that can fit a wide variety of applications, such as boat trailers and utility trailers, as well as campers, with weight rated in the 3,500 to 12,000 pound range. The Draw-Tite 2-inch ball (model 63845), for example, can hold 7,500 pounds and has a 1-inch shank diameter and a shank length of 2-1/8-inch. In all cases, ensure that your coupler is 2 inch ball sized and that the weight rating of the ball used is equal or higher than the weight of your loaded trailer. The popularity of the product implies that accessories and substitutes are easily accessible 14.

🔧 Tri-Ball Trailer Hitch Systems

A tri-ball trailer hitch is very convenient to those people who drag various trailers with different coupler sizes. These systems consist of three balls that are held on a single platform- they generally have the 1-7/8-inch, 2-inch, 2-5/16-inch size. It will reduce the use of changing balls when changing trailers. To illustrate, the ORCISH tri-ball mount fits a 2-inch receiver and is capable of supporting up to 10,000 pounds, which works best with RVs, SUVs, and trucks. But also make sure that the multi-ball system has the weight capacity to carry your heaviest trailer. Although convenient, these systems need to be well secured with a strong hitch pin and checked frequently to ensure wear and tear since they are a known source of concentration of stress at various points 3.

💡 Hitch Ball Materials Matter

Hitch balls are made using high-strength steel and in many cases have protective finish to prevent corrosion and wear. Popular finishes are chrome plating, powder coating and stainless steel. Chrome plating gives a glittery rust-free surface that is also resistant in most circumstances. Powder coating is a more protective coating and is also thicker, resistant to rough weather and off-road conditions. Stainless steel balls are extremely resistant to corrosion, perfect when used in the ocean or road salt. Not only the material and finish have an impact on the durability, but also safety, as a corroded or weakened ball can break under its weight. Use a ball that is as strong and as durable as or stronger and more durable than industry standards 6.

🚗 Installation and Safety Tips

To ensure safe towing, it is important that you install your hitch ball properly. First, choose the right ball to the right amount of weight and coupler. Slide the shank of the ball through the hole on the ball mount or bumper hitch, making sure that it fits right in. Install it in the given hex nut and lock washer and screw it into place to the recommended torque of the manufacturer- typically around 250 ft-pounds on larger balls. The latter can be accomplished using a torque wrench. Check the nut tight before each tow and check the ball, cracks or corrosion. Also, make sure that the coupler latches are locked onto the ball without any excessive play. Check the lubrication of the moving parts of the coupler regularly to keep moving parts not sticking to each other and allow unit to move freely 14.

🔄 Maintaining Your Hitch Ball

The key to the long life of your hitch ball and future security is maintenance. Clean the ball of dirt and debris after each use using a wire brush; this can grind against the coupler and wear it out. A small coating of grease should be applied to avoid rusting and decrease the friction between couples and uncouples. But do not put grease on the upper part of the ball, lest it take the dirt. Always keep your hitch ball in a dry place whenever you are not using it to avoid corrosion. In the case of multi-ball systems, ensure that all bolts/hitch pin are tightened before use. Annually check the ball against wear, including scoring, rust pits, etc., which may wear the ball and undermine its integrity. Change the ball when any damage is observed 16.

Difference Table

| Feature | 1-7/8″ Ball | 2″ Ball (The All-Star) | 2-5/16″ Ball (The Heavy Hauler) | 3″ Ball (The Specialist) |

| What It’s Best For | Small jobs! Jet skis, tiny utility trailers, lightweight gear. | Your go-to for most trailers: boats, campers, mid-sized utility. | Big travel trailers, large horse trailers, serious equipment. | Exclusively for gooseneck and fifth-wheel trailers. |

| Weight Capacity | Up to 3,500 lbs | 3,500 – 12,000 lbs | 6,000 – 30,000+ lbs | Extreme loads (~30,000 lbs) |

| Compatibility | Class I & II hitches | Fits most Class III hitches (the most common type) | Class IV and V hitches | Special gooseneck hitch installed in your truck bed |

| Ease of Use | Super simple, but only does one job. | The most versatile; parts and accessories are everywhere. | Heavy-duty; requires a bigger, stronger hitch system. | Not for everyday use; a dedicated setup for big rigs. |

Conclusion

When selecting automotive towing equipment hitches balls, it is important to have the right equipment to ensure that the towing process is safe and effective. The key to choosing the right standard size is knowing the sizes available, especially the popular 2 inch trailer hitch ball, and taking into account the size weight capacity and material used in the process. Tri-ball trailer hitch systems provide convenience and flexibility to individuals with various towing requirements. Proper installation and regular maintenance is always important to ensure your towing setup is reliable. Now you know what to consider when choosing the ideal hitch ball to adventure with, and you will be free on the highway. Happy and safe towing!

FAQ’s

1. What is the most common trailer hitch ball size?

The most popular and universal is the 2-inch trailer hitch ball that fits most class III hitches and trailers including boats, campers, and utility trailers.

2. How do I know which hitch ball size to choose?

Always be sure that the hitch ball is the same size as the coupler on the trailer. Make sure the coupler is correctly stamped in size (e.g. 2 inch or 2-5/16 inch), and make sure the weight carrying capacity of the ball is greater than the weight being carried by your trailer.

3. Can I use a tri-ball hitch for all my trailers?

Yes! A tri-ball hitch puts three sizes of the common ones (typically 1-7/8 to 2-5/16) on one mount, so that when you change trailers, you need only to verify the weight rating first.

4. How tight should I make the hitch ball nut?

Tighten the nut to the specification of the manufacturer using a torque wrench- normally 250 ft-pounds on larger balls. This keeps it tight and does not loosen as it is being pulled.

5. How often should I maintain my hitch ball?

Each time the ball is used, it should be wiped down and oiled to avoid rust and wear. Before attaching a trailer to it, always check to see if it is damaged, such as having cracks or deep rust.